HZI Re-Sourcing Solutions

HZI Re-Sourcing Solutions

We Recover Useful Materials from Bottom and Fly Ash

From a Waste to a Resource Economy

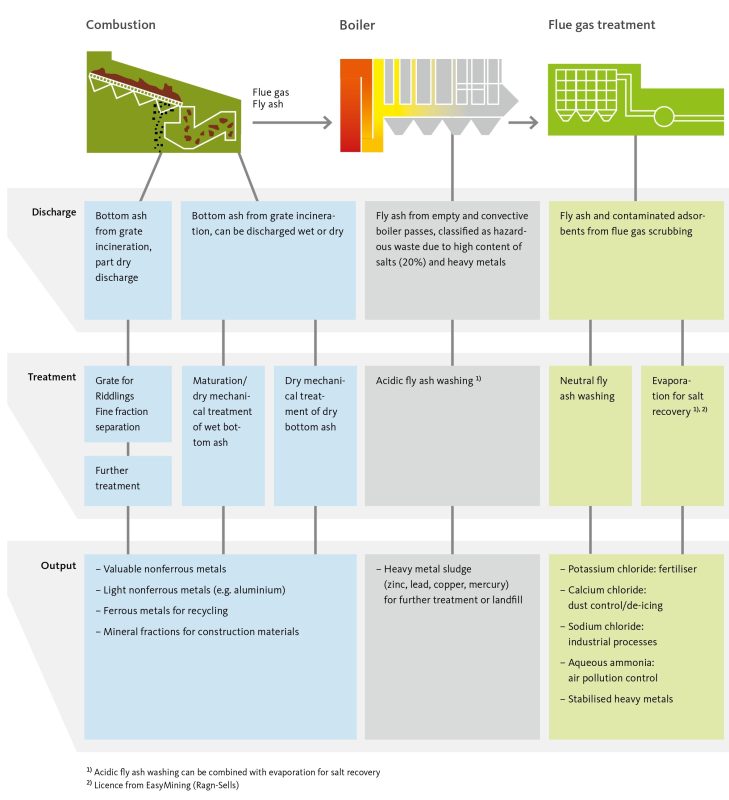

The residues of the Waste to Energy (WtE) combustion process are much more than bottom and fly ash. They contain valuable metals, salts and minerals. Hitachi Zosen Inova offers its customers innovative processes and technologies to recover these useful materials. Additional sources of revenue from the sale of these recyclables and reduced disposal costs further improve the efficiency of your plant.

Why Is “Urban Mining” the Bottom and Fly Ash Worthwhile?

Recovering recyclable materials from residues is an increasingly relevant part of urban mining for operators of WtE plants. This urban mining has four key benefits:

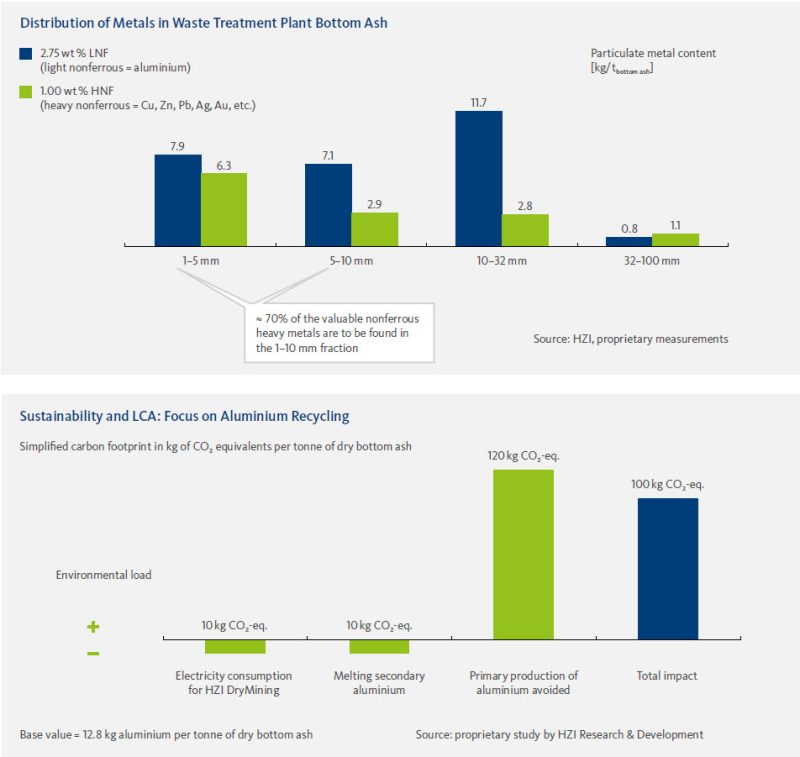

– Generates additional revenues from the sale of recovered materials such as iron, copper, aluminium, gold, minerals and salts

– Reduces disposal costs thanks to lower quantities of residue

– Makes a relevant contribution to environmental protection and sustainability. By providing recyclable materials, the operator contributes to the conservation of resources, reductions in CO₂ emissions and the circular economy principle

– Meets the legal requirements governing the recovery of recyclables from waste, which are already mandatory in some countries and regions

The benefits of urban mining the residues of WtE plants depend on various factors such as the efficiency of the recovery technologies, the cost of processing the residues and the availability of markets for the recycled materials. Hitachi Zosen Inova (HZI) offers thorough planning services and technical solutions to maximise the benefits for the plant operator.

If the volumes of residue generated locally are not sufficient for cost-efficient processing, residues from surrounding WtE plants can be processed economically at a centralised processing plant.

Factors in Successful Urban Mining of Bottom Ash

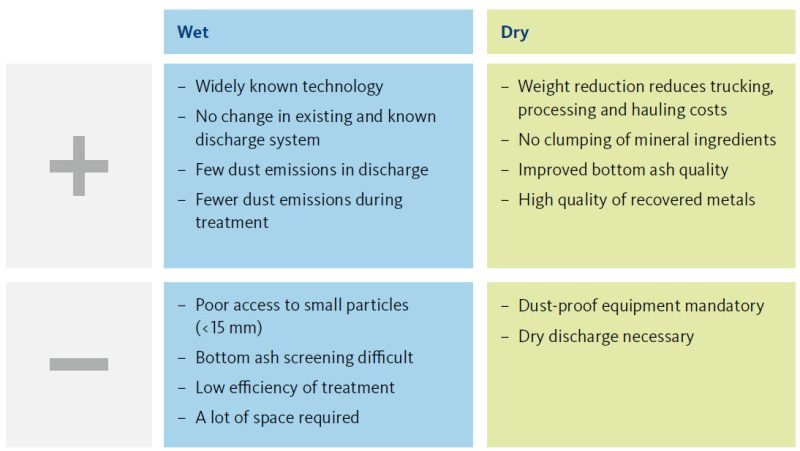

Basically the bottom ash discharge can be wet, dry or a combination. There are pros and cons to each.

Combined discharge makes it possible to harness the advantages of both the wet and dry processes. The focus is on ensuring efficient but resourcefriendly discharge by first discharging the fine fraction of the bottom ash (particle size of less than 15 mm) in dry form via the Grate for Riddlings.

Around 70% of valuable nonferrous metals, such as aluminium and copper, as well as silver and gold, are to be found in the fine fraction. The rest of the bottom ash is discharged using the conventional wet method.

HZI grate with integrated HZI Grate for Riddlings, Emmenspitz/Zuchwil, Switzerland

HZI’s dry mechanical treatment system enables the effective recovery of minerals and metals from bottom ash extracted using the wet discharge method.

These can then be processed further directly and/or recycled as secondary raw materials and materials for use in construction. Compared with purely wet discharge, the combined solution results in less mineral adhesion to fine metal particles. This improves the quality of the fine fraction thanks to greater enrichment of valuable metals, while at the same time reducing operating costs.

Factors in Successful Urban Mining of Fly Ash

In addition to bottom ash, a modern waste treatment plant always produces fly ash and residues from flue gas cleaning. These account for about 2–3% of the incinerated material. Given the high proportion of salts (more than 20%) and heavy metals it contains, fly ash is classified as hazardous waste and must be disposed of as such. This involves substantial costs. HZI has been offering fly ash washing systems for several decades already.

While processes used to focus purely on “stabilising” the hazardous substances, they have been optimised to the extent that metals and salts can now be recycled. The remaining treated residue can then be landfilled as so-called inert material.

In neutral fly ash washing, the dusts or ashes are washed with water. In the process all soluble salts (mainly chlorides) are washed out and the residual material can be landfilled or reused. This process makes sense especially if the residues contain relatively few heavy metals.

In acidic fly ash washing, the dusts or ashes are washed with a dilute acid. This dissolves all soluble salts and a relevant part of the heavy metals. The heavy metals are precipitated as hydroxide sludge and can thus be fed into the metal recovery process. The latest technology in its portfolio is the Ash2Salt process. It was developed by EasyMining, the innovation arm of Ragn-Sells, and is distributed exclusively by HZI in Europe. This process enables both neutral and acidic fly ash washing to be expanded to a decisive extent.

In both processes, a liquid residue with a high chloride content is produced in addition to the washed ash. As a rule, this may not be discharged back into nature or into the sewage system without further treatment. The Ash2Salt process recovers sodium, potassium and calcium chloride from this liquid residue.

The process thus works without generating wastewater needing to be discharged. The salts recovered are of high enough quality to be used commercially (road de-icing in winter, fertiliser industry, etc.).

References

Emmenspitz / Zuchwil: Grate for Riddlings

At the Emmenspitz WtE plant in Zuchwil (line 4), a Grate for Riddlings is used on the fifth zone of the grate. This is used to screen 30% of the total bottom ash as a fine fraction before it is discharged into the wet bottom ash discharge system. At a waste throughput of 8.8 tonnes, this amounts to almost 550 kg. This fraction contains a particularly large amount of high-grade metals. Dry discharge allows both light and heavy nonferrous metals to be recycled directly. The >15 mm fraction of the bottom ash is discharged via the existing wet discharge system.

Högbytorp: Dry Bottom Ash Discharge

The plant in southern Sweden processes 30.8 tonnes of municipal waste and biomass per hour. When it was commissioned in 2020, Europe’s largest dry bottom ask discharge system also went into operation. Every hour, almost 6 tonnes of bottom ash are discharged from the treatment process in an airtight conveyor belt system and made available to Ragn-Sells, which recycles the product and extracts metals and other useful materials from the bottom ash. The dry discharge process preserves fine fractions in particular, which contain valuable metals.

Poznań: Wet Bottom Ash Discharge

The first WtE plant built by HZI in Poland converts 210,000 tonnes of waste per year into power and heat. The plant produces 57,750 tonnes of bottom ash a year. The installation uses a wet bottom ash removal process. The bottom ash is removed, matured and dewatered, and then a drum sieve is used to separate it into fractions of 150–300 mm, 40–150 mm and 0–40 mm depending on the size of the particles. Various processes are used to separate ferrous and nonferrous metals from the bottom ash.

Liberec: Fly Ash Washing

The plant, located in a mixed residential and commercial area, treats municipal waste from the Liberec region. A special feature is an acidic fly ash washing unit that removes heavy metals from the boiler ash and fly ash, enabling them to be mixed with the bottom ash. The residues from the subsequent waste water preparation process are landfilled.

Högbytorp: Ash2Salt

At the Salarium treatment plant in Högbytorp, air pollutant control residues (APCRs) are washed in neutral water. This produces purified ash and a leachate containing mainly chloride salts and heavy metals, which is sent to the second stage. There heavy metals are precipitated from the leachate. Calcium chloride, potassium chloride and sodium chloride are then separated from the resulting chloride-saturated liquid. The has a processing capacity of 130,000 tonnes per year. Fly ash from other waste incineration plants is also utilised in addition to fly ash from Högbytorp.