Waste to Energy

Waste Throughput

Energy Recovered

Thermal Power

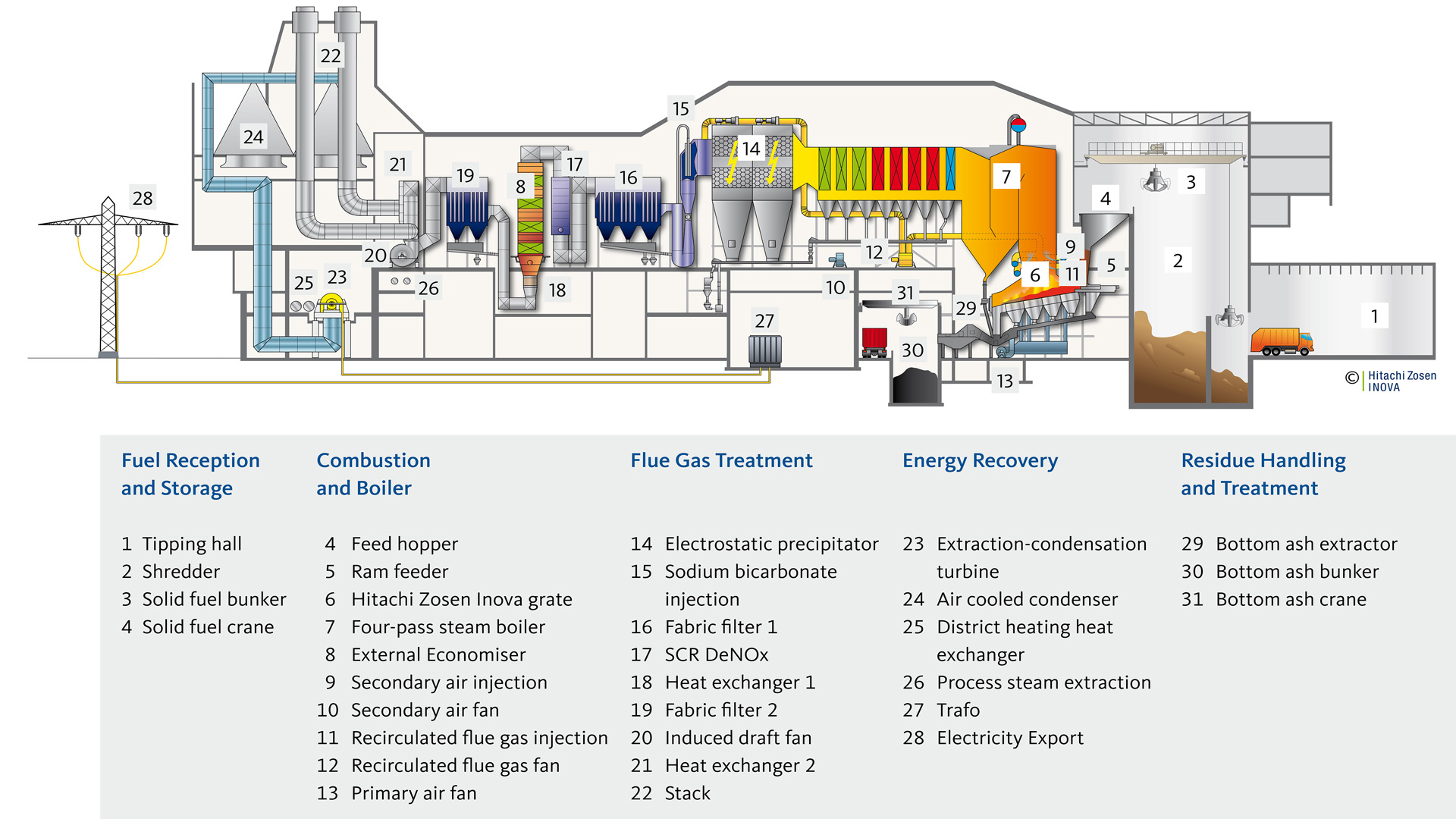

The output of this two-line WtE plant right next to a paper factory includes process steam for the paper industry. Thanks to a two-stage dry sorption process and the placement of two additional heat exchangers in the flue gas path, the plant can boast very high energy efficiency and very low emissions.

Facts

- Type of system: water-cooled HZI reciprocating grate

- Fuel: municipal waste, commercial waste

- Calorific value: 10.85 MJ/kg

- Number of lines: two

- Boiler design: four-pass boiler with external economiser

- Flue gas treatment: electrostatic precipitator, dry sorption with injection of sodium bicarbonate, fabric filter 1, SCR DeNOx, external economiser, heat exchanger 1, lime and lignite coke injection, fabric filter 2, heat exchanger

- Renergia Zentralschweiz AG

- 2015; performance enhancement: 2018

- complete combustion, boiler and flue gas treatment, including supply of chemicals and transport and storage of residues