Zistersdorf / Austria

Zistersdorf / Austria

Zistersdorf Waste to Energy plant – a centralised facility for the thermal treatment of supra-regional waste.

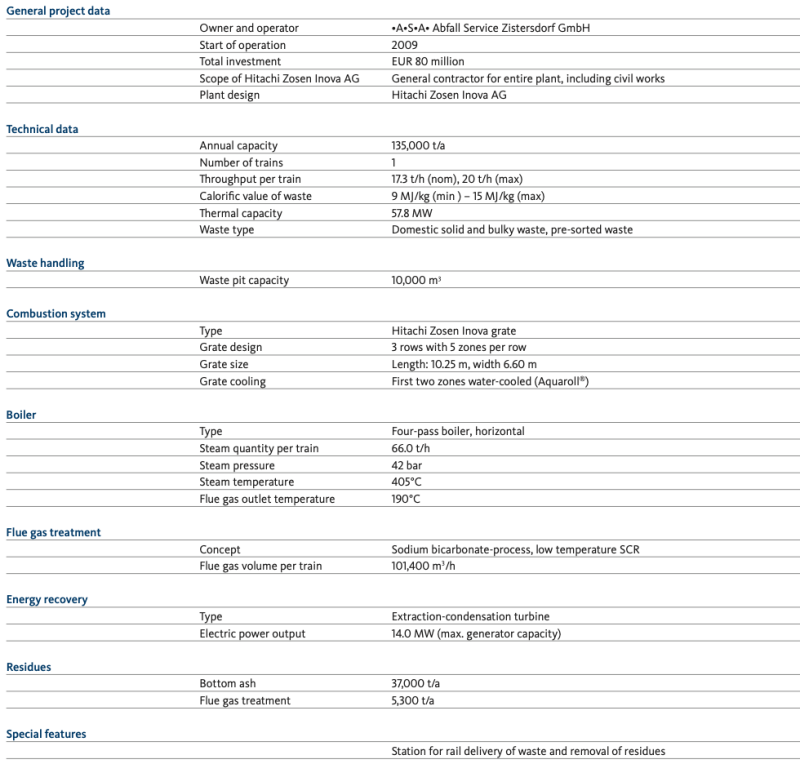

The Zisterdorf Waste to Energy plant is proof of a successful co-operation between waste management and waste treatment. The facility, located 60 km north-east of Vienna, is capable of treating up to 135,000 tons a year of domestic solid waste and processed waste while at the same time exporting sufficient electricity to power more than 25,000 homes.

•A•S•A• (Abfall Service AG) of Austria, a subsidiary of Fomento de Construcciones y Contratas S.A. of Spain, is one of the leading waste management companies in Central Europe. Besides waste collection services, ASA also operates several material recycling and biological treatment facilities. The Waste to Energy plant in Zistersdorf is the first facility of this kind for ASA and is further proof of the expansion policy with regard to environment-friendly technologies.

Hitachi Zosen Inova (formerly Von Roll Inova), has assumed the role of an EPC contractor and is responsible for the entire turnkey facility. Construction time was 2 years and commissioning began in January 2009. Commercial operation commenced in April 2009.

Sophisticated logistics for maximised availability.

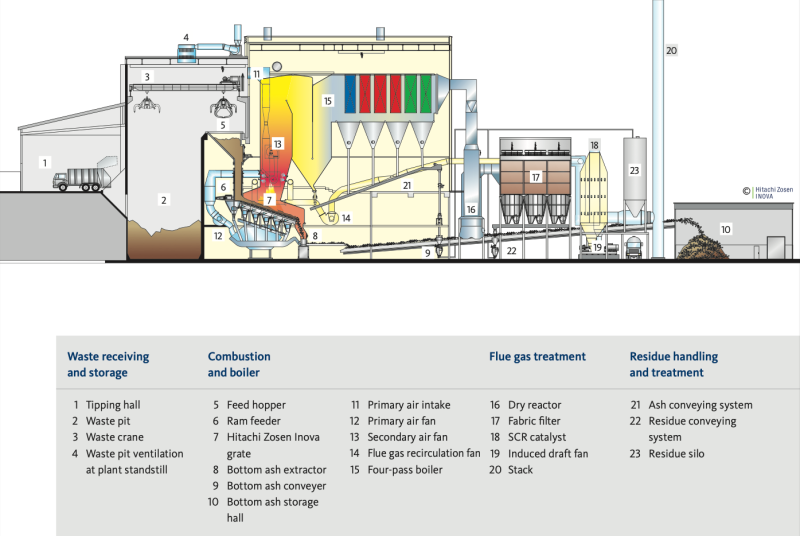

The majority of the waste, approximately 70%, is brought by train from remote material recycling facilities or transfer stations directly to the plant. As a consequence, road traffic is kept low. Non-recyclable processed waste from material recycling facilities is delivered to the plant in plastic wrapped bales. Four tipping bays ensure short waiting periods and two independent waste cranes maintain the smooth feeding of the process train.

Modern technology for safe, ecological and economical energy recovery.

The 57.8 MW thermal treatment plant consists of a single process train with a capacity to treat 20 t/h of waste. The waste is combusted on a three-row five-zone reciprocating grate, of which the first two zones are water-cooled. A fully integrated control system allows for rapid adjustments of combustion conditions for the safest and most efficient operation possible.

This process reduces the volume of the waste by 90%; the remaining bottom ash is treated adjacent to the site for further use in the road construction industry. Ferrous metals are then separated for recycling and treatment residues are shipped off site for disposal in sealed containers via railway.

A four-path horizontal boiler recovers energy from the flue gases. The dry air pollution control system ensures safe compliance with the emission limits defined by the authorities. In fact, these limits are well below EU emission standards and must be fulfilled independent of the waste composition.

The flue gas treatment comprises two stages: After injection of sodium bicarbonate and lignite coke, acid gas reaction products, adsorbed dioxins and heavy metals as well as particles are separated in a fabric filter. Thereafter NOx levels are reduced in a low temperature Selective Catalytic Reduction (SCR) system.

Waste to Energy.

The Zistersdorf Waste to Energy facility uses the thermal capacity of the treated waste fractions to generate electricity. 12.8 MW of electrical power is supplied to the national grid, an amount sufficient to cover the needs of more than 25,000 homes.