Lausanne / Switzerland

Lausanne / Switzerland

Tridel – environmentally-friendly thanks to maximized metals recovery and minimal emissions

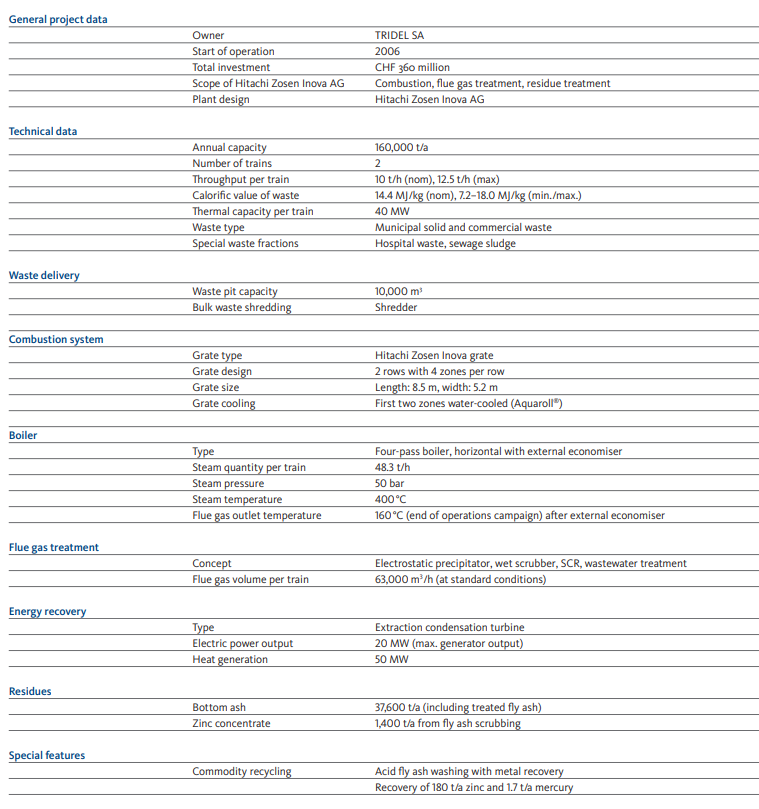

High energy efficiency, low emissions, virtually no visible plumes of steam: The new Waste to Energy plant in Lausanne, in the Canton of Vaud (CH), meets all the standards for a facility located near this urban recreational area. Built using the latest technology, this new plant has now replaced what was once the world‘s oldest one still in operation.

Pioneer in thermal waste treatment.

Lausanne became a pioneer in thermal waste treatment when its plant, designed by Hitachi Zosen Inova, went online in 1958. Forty-eight years later, it had become the world’s oldest incinerator still in service. In 2006 when it was replaced by a larger and more efficient new facility capable of treating most of the waste generated in the canton of Vaud.

Strict requirements imposed on new plant.

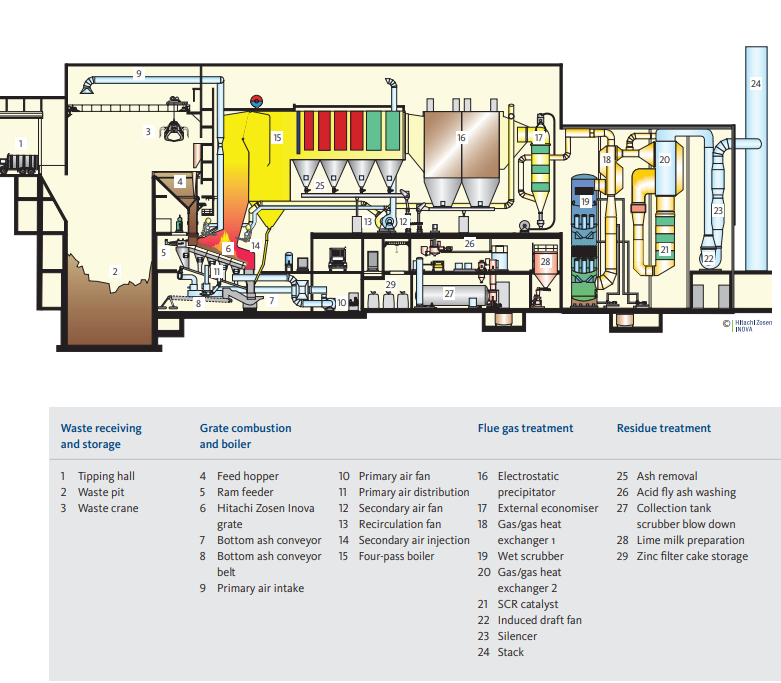

The new facility had to meet ambitious Tridel SA expectations: very low emissions, maximized energy output, economical operation and high availability. The decisive factors in awarding the contract to Hitachi Zosen Inova were the company’s proven technology, experience, a high degree of technical competence and a long-standing partnership. The new plant comprises two process trains, each with a capacity of 12.5 Mg/h, a boiler in a cogeneration scheme, a flue gas treatment unit ensuring minimal emissions, and a system to recover reusable materials.

Environmental protection begins with delivery.

A key asset of the plant is environmentally safe delivery of the waste by rail. Three-fourths of the waste, from around 150 communities in the Canton of Vaud, arrive at the plant via a 4-km long rail tunnel beneath the city.

Optimized combustion and low emissions.

The waste is conveyed from the dumping pit through the feed hopper and into the two combustion chambers, each equipped with a Hitachi Zosen Inova grate. The grates consist of four individually controlled zones. The first two are water-cooled to ensure consistent and optimal burnout of the wastes at over 1000°C. Each of the two four-pass horizontal boilers features a secondary combustion chamber, which guarantees maximal flue gas burnout, two additional radiation passes, and a horizontal convection zone. Downstream of the electrostatic precipitators, an external economizer optimizes the energy recovery. In the second stage, the flue gases are treated in a three-stage wet scrubber and then denitrified in the catalyst. A gas/gas heat exchanger upstream of both stages aids in heat recovery. This plant design meets Switzerland’s tough flue gas treatment without difficulty, and most emission levels are in fact just a fraction of the mandated limits.

Rain supplies fresh water.

The wet scrubber at Lausanne is the first in a Hitachi Zosen Inova plant to use rainwater as a utility. The environmentally conscious design collects 6,000 m3 of water annually, i.e. water that does not

have to be taken from the public mains and softened. The innovation is not only ecologically beneficial but will actually pay for itself over the plant’s lifetime.

Maximized energy and recovery of reusable substances.

Designed for maximal energy efficiency and minimal emissions, the plant produces 82,000 MWh of electrical energy and 247,000 MWh of heat per year. Its output supplies 18,000 households with electricity and heat. What is more, some 1,700 kg of mercury and 180 metric tons of zinc per year are recovered in Lausanne through fly ash washing and then recycled.