Incinerating waste produces exhaust gases laden with diverse pollutants. Different processes are used to remove these pollutants before the purified flue gas leaves the plant safely through the stack.

For decades HZI has been doing research into flue gas treatment and developing new and effective treatment systems. We harness internal synergies to optimally match and combine our combustion and flue gas treatment equipment. The numerous processes that have emerged can be used individually or together to create high-performance integrated systems.

The appropriate flue gas treatment approach is chosen in close consultation with the client. The selection criteria include regulatory air pollution limits, the client’s expectations regarding the energy efficiency of the plant, restrictions on waste water discharge, and the space available on site – to name only a few.

Typical Pollutants in the WtE Process – and What We Do to Address Them

Various pollutants are introduced into the combustion process by the waste, including oxidised combustion products such as SO2and NOxproducts, as well as substances such as hydrogen chloride and hydrogen fluoride, heavy metals, dioxins and furans. We use specific types of treatment to separate these pollutants out during the WtE process and then dispose of them appropriately. Our comprehensive range of processes enables us to cover a broad spectrum of requirements.

Dust

Dust

- Fabric filter

- Electrostatic precipitator

Corrosive

Acid

Gases

Corrosive Acid Gases

- Dry sorption

- Semi-dry sorption process

- Wet scrubber

Organic

Carbon

Compounds

Organic Carbon Compounds

- Adsorption onto activated carbon or lignite coke

Mercury

Mercury

- Adsorption onto activated carbon or lignite coke

Other

Metals

Other Metals

- Removed with flying dust in a fabric filter or electrostatic precipitator

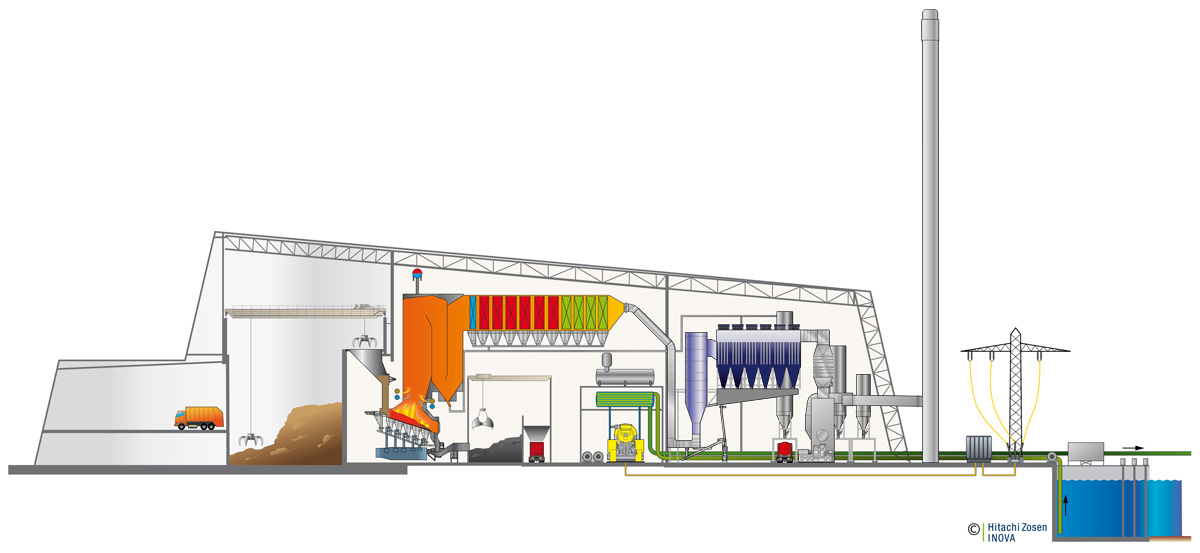

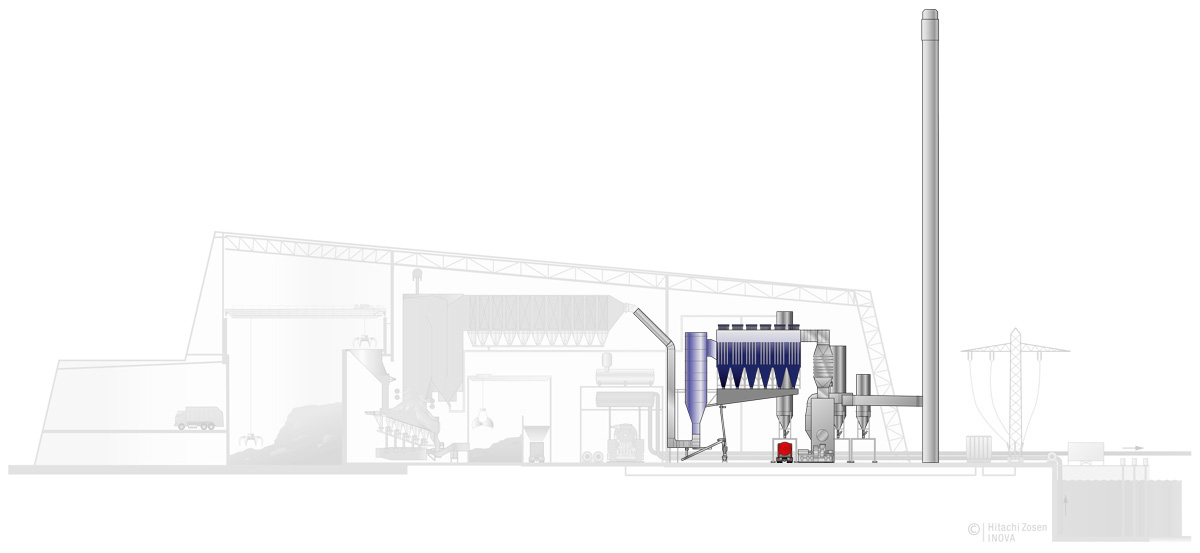

Integrated Flue Gas Treatment Systems

Thanks to many years of experience, HZI can now offer a wide range of high-performance processes for reducing emissions. On the basis of the individual requirements and circumstances of each plant, we develop tailored integrated flue gas treatment approaches. When putting together the right overall approach we take account of the following factors:

- What is the key performance indicator for flue gas treatment? For example achieving the lowest possible emissions, optimising energy efficiency, or minimising the investment in the process, etc.?

- Type of waste, including any pretreatment

- Type of combustion process, plus waste throughput and thermal capacity

- What emission limits are to be complied with?

- Volume flow of flue gas and temperature of flue gas at the boiler

- Temperature profile along the flue gas path

- Availability and cost of water, materials/reagents and fuels/energy sources

- Availability and cost of disposing of or processing residues generated or recovered

- Energy supply options (for example feeding into a district heat network, supplying heat from a condensing scrubber, etc.)

- Restrictions on wastewater discharge

- Available space (surface, limitations due to existing design of building, etc.)

Each flue gas treatment module serves a specific purpose. Flue gas cleaning achieves the highest performance when the various components are combined – on the basis of the individual requirements of the plant. In this way, even the lowest BREF emission values can be achieved without difficulty.

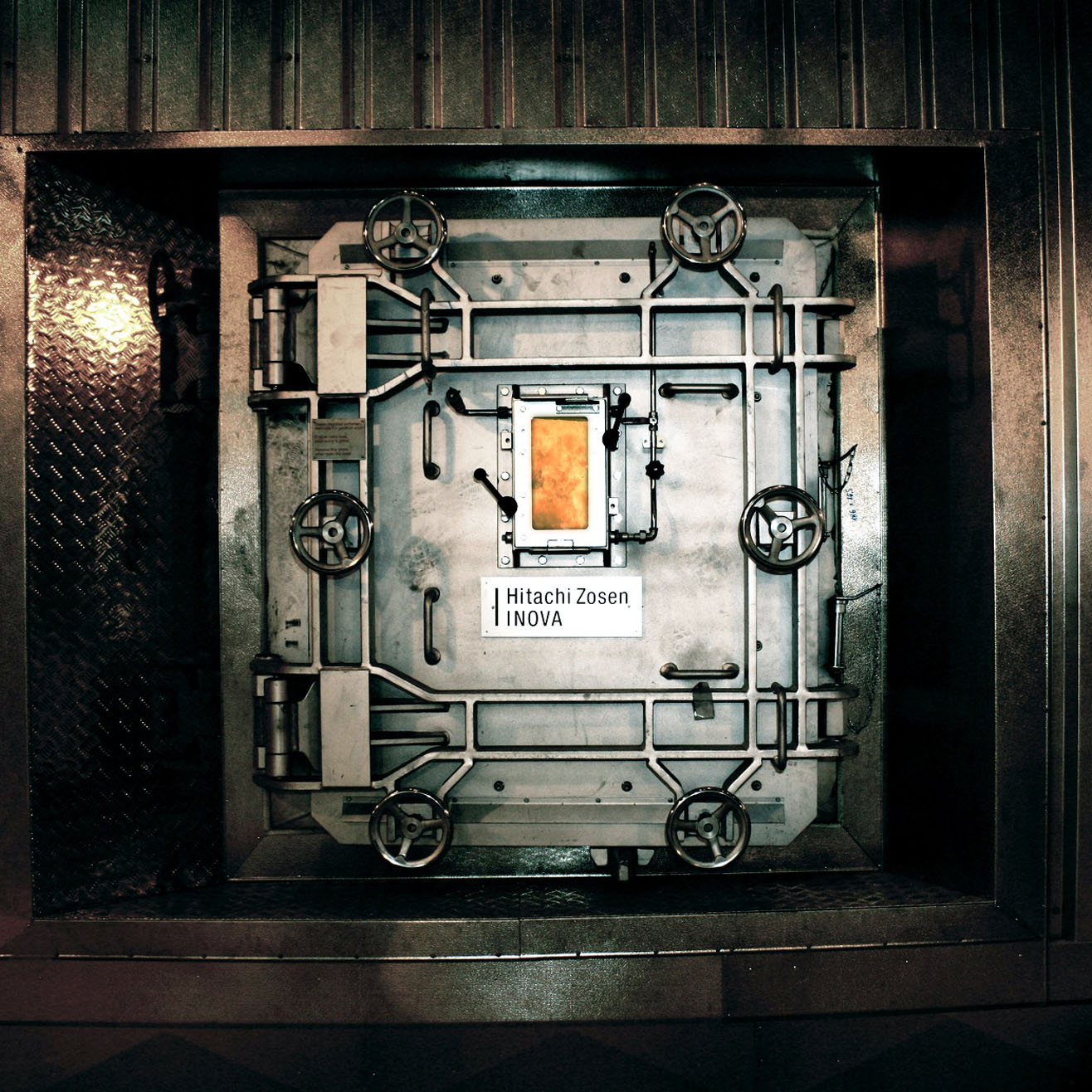

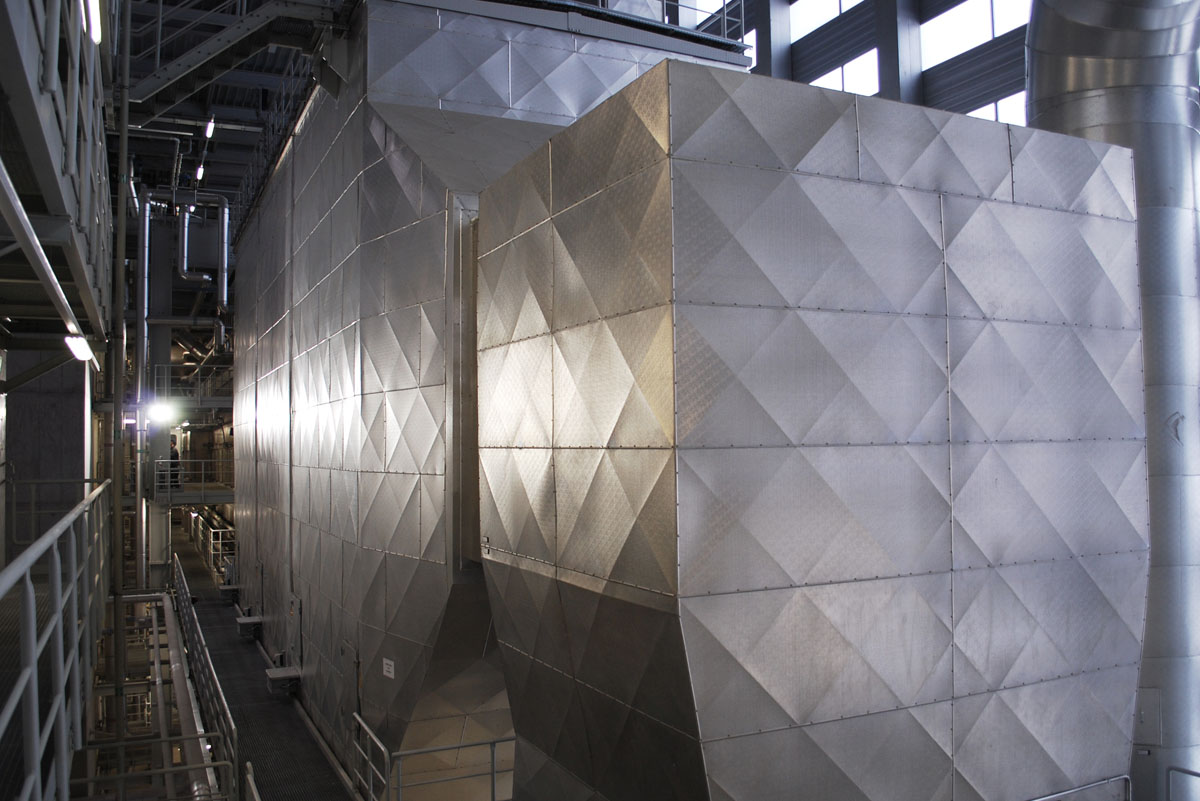

Fabric Filter

HZI’s fabric filter is a product developed by Hitachi Zosen Inova to remove solids (dust) from the flue gas. It is a physical separation process where the solids are filtered out at the surface of a gas-permeable fabric.

If the fabric filter is used in a dry sorption (the XeroSorp process) or semi-dry sorption (HZI SemiDry) process, a filter layer of reagents and fly ash forms on the filter bags, where the separation of pollutants takes place.

The Main Advantages of HZI’s Fabric Filters:

- Low wear and tear

- Easy-maintenance

- Filter chambers can be individually isolated during full-load operation to check for defective filter bags

- Software for fully automated filter control and cleaning

Electrostatic Precipitator

In an electrostatic precipitator particles are ionised – in other words electrostatically charged – and then separated out under the influence of an electric field. The electrostatic precipitator, comprising two or three electric fields, is usually placed directly downstream of the boiler.

The Main Advantages of the Electrostatic Filter:

- High separation efficiency for solids and dust

- Constant separation even when there are changes or fluctuations in load

- Low operating and maintenance costs

- Long lifetime and high availability

Dry Sorption (XeroSorp)

In HZI’s XeroSorp dry scrubbing process, corrosive acid gases (for example HCl, HF and SO2) are neutralised with the help of adsorption additives.

The term “xero” is a Greek prefix derived from the word “ξηρός” (xērós), meaning “dry”. As the name suggests, the process does not involve the introduction of any water at all. Instead we use two different adsorption additives for neutralisation: hydrated lime and sodium hydrogen carbonate (commonly known as sodium bicarbonate).

Depending on the additive used for neutralisation we call the process:

- XeroSorp lime (if hydrated lime is used), or

- XeroSorp bicar (if sodium hydrogen carbonate is used).

The Main Advantages of the XeroSorp Process:

- Low operating and maintenance costs thanks to simple design and operation

- Low process investment and minimal infrastructure costs thanks to compact design

- Minimal use of adsorption additives and very low residue generation

- XeroSorp bicar reaches even the low BREF emission values under optimal conditions

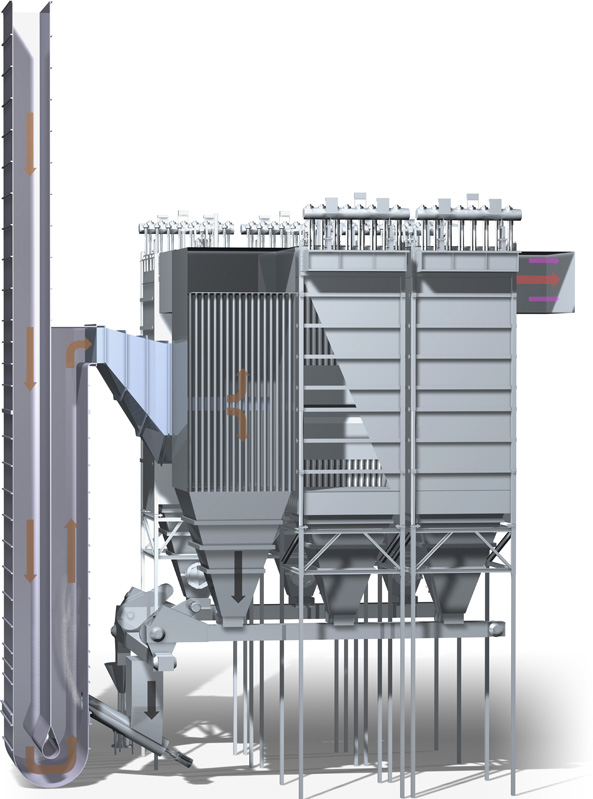

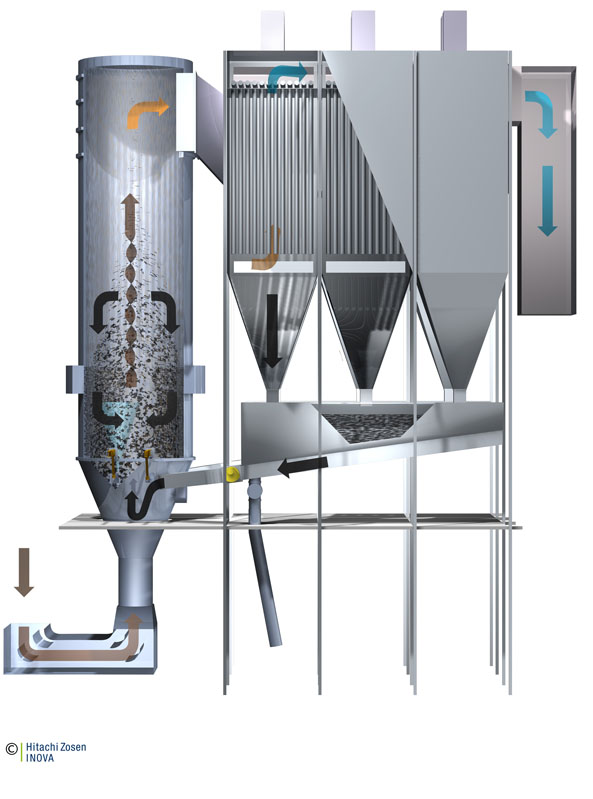

Semi-Dry Sorption Process (HZI SemiDry)

The HZI SemiDry system involves a semi-dry sorption process employing the principle of the circulating fluidised bed.

Hydrated lime is injected into the fluidised bed reactor to neutralise corrosive acid gases. The temperature in the reactor is key to the sorption process. To achieve the ideal reaction temperature (typically 145°C), water is sprayed into the reactor simultaneously. In addition to regulating the temperature, the water reactivates the recirculated residues, optimising the separation efficiency of the process.

The Main Advantages of HZI’s SemiDry Process:

- Low emissions and high efficiency if there are changes in the concentration of pollutants in the flue gas (high buffer capacity to prevent spikes resulting from the large quantity of solids in the system)

- Low sensitivity to fluctuations in temperature on entering the reactor (temperature regulated by injection of water)

- High energy efficiency compared with lime slurry-based systems

- High availability and low operating and maintenance costs thanks to use of proven equipment with only a small number of mechanical components

- With a stand-alone SemiDry system, the upper BREF limits can be achieved.

- By retrofitting a DC scrubber, the low BREF values can also be achieved – thanks to the combination with the SemiDry, still wastewater-free

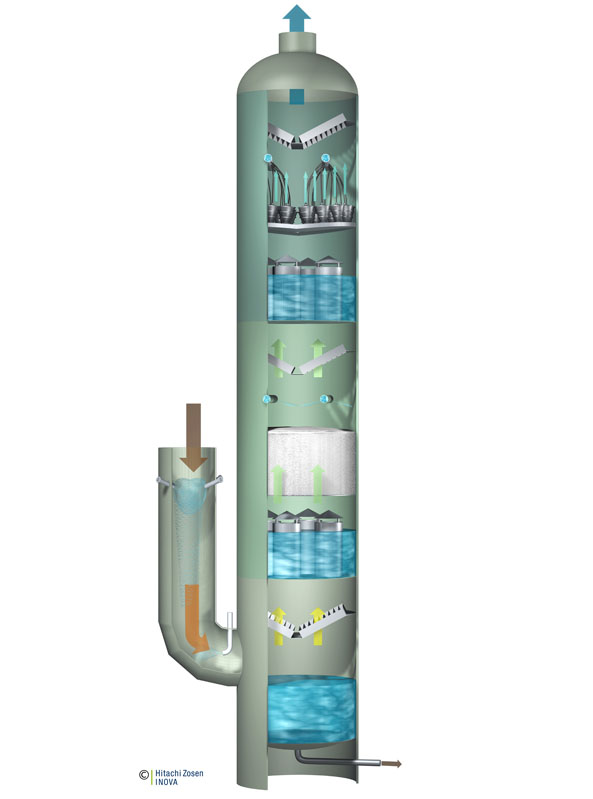

Wet Scrubber

Wet scrubbing is the most effective method for removing acid gases from even heavily burdened flue gases. It achieves the lowest emissions, and is also excellent when it comes to removing particulates and aerosols.

Wet scrubbers consist of several stages, each of which fulfils a particular purpose: separating out specific pollutants, saturating flue gases, or extracting heat. Each scrubber stage therefore features specific equipment, for example nozzles, liquid distributors, packed beds, ringjets, droplet separators, etc. Thanks to different forms of intensive contact of the flue gases with water, pollutants are captured and separated extremely thoroughly.

The individual scrubber stages have their own water circuits. An overarching water distribution system ensures that all stages are supplied with sufficient water and that the separated pollutants are separated via the scrubber blowdown. The scrubber blowdown products are treated in a waste water treatment unit before final discharge.

HZI basically offers three different types of wet scrubber:

- The multiple-stage counterflow scrubber for the main separation of pollutants

- The two-stage parallel flow scrubber for separation of residual pollutants (polishing scrubber)

- The single or multiple stage condensing scrubber for extracting flue gas heat

The Main Advantages of the HZI Wet Scrubber:

- Pollutants are separated systematically in several stages

- Achieves very high separation rates for acid gases (low emissions)

- Constant separation even when there are changes or fluctuations in load

- Low volumes of residue thanks to stoichiometric consumption of chemicals

- Significantly boosts plant efficiency if condensing stage or condensing scrubber is fitted

- Low-maintenance process with high availability

- Any desired combination of different stages is possible to adapt to process and client requirements

- Highest separation rates for acidic pollutant gases (guaranteed compliance with the lowest BREF emission values)

SNCR Process

In the SNCR (selective non-catalytic reduction) process, nitrous oxides (NOx) react with ammonia and are chemically converted into nitrogen (a natural constituent of air) and water vapour.

For efficient denitrification (DeNOx), it is crucial to operate in the right temperature ranges. If the temperature is too high, the ammonia is “burned”. If the temperature is too low, the reaction slows and a large portion of the ammonia reaches the stack unused. The ideal temperature range is to be found in the post-combustion chamber, although there it is subject to fluctuation because of variations in load and fuel. To prevent this, the reducing agent (ammonia water or urea) is injected into the post-combustion chamber at various points.

But even within the optimum temperature range, the NOx separation rate with a conventional SNCR process is limited. Achieving higher NOx removal efficiency requires injecting more ammonia than is consumed. The excess can be removed downstream in a wet scrubbing process. In our patented process, the ammonia is recovered from the effluent and can be re-injected into the post-combustion chamber.

The Main Advantages of the HZI SNCR Process:

- Low process investment and minimal infrastructure costs thanks to simple process technology and integration of the process in the post-combustion chamber of the boiler

- Simple, precise control of the various stages via the distribution modules

- In combination with a wet scrubbing process and ammonia stripper, very low NOx limits can be achieved and the excess ammonia can be recovered

- The system can be upgraded to create a DyNOR® process meeting even lower NOx limits

DyNOR® Dynamic NOx Reduction

The DyNOR® system developed by Hitachi Zosen Inova’s engineers is an improved SNCR process. It enables nitrogen oxide to be reduced to very low levels with minimal ammonia slip, something that was previously only possible with an SCR process. The non-catalytic DyNOR® process closes the gap between the costly SCR process and the conventional SNCR process. It is an investment that pays off.

The Main Advantages of the DyNOR® Process:

- Meets low NOx limits, even without a catalytic converter

- Allows compliance with the higher BREF limits

- Investment costs and energy consumption significantly lower than with the SCR process

- Uses less ammonia than the conventional SNCR process

- Given the minimal ammonia slip and very low NOx levels, no wet scrubber or ammonia stripper are required

SCR Process

Selective catalytic reduction (SCR) is the most effective DeNOx process. Nitrous oxides (NOx) are converted into nitrogen and water vapour at a catalytic surface, with ammonia water or urea used as a reducing agent.

Using a catalytic converter allows the reduction of nitrous oxides at significantly lower temperatures, and is considerably faster than the SNCR process. DeNOx rates of more than 90% can be achieved. Other advantages of the process are low consumption of ammonia water (almost stoichiometric) and low ammonia slip. If the catalytic surface is sufficiently large, part of the dioxins and furans are destroyed at the same time.

The SCR process is flexible in terms of operating temperature, and can be deployed at various points along the flue gas treatment process chain. On this basis a distinction is made between the following approaches:

Raw gas catalytic converter:

- At the boiler outlet, with upstream electrostatic precipitator

- Operating temperature approx. 260-300°C

Clean gas catalytic converter:

- After prior dust and SO2separation

- Operating temperature approx. 240-250°C

Low temperature catalytic converter:

- After prior dust and SO2separation

- Operating temperature approx. 180-190 °C

- Periodic regeneration at approx. 320°C required

The Main Advantages of the SCR Process:

- Achieves very high removal of nitrous oxides

- Low consumption of ammonia water (almost stoichiometric) and low ammonia slip

- Simultaneous removal of nitrous oxides (NOx) and dioxins/furans

- Optimum integration in the overall flue gas treatment system thanks to availability of different approaches (raw gas, clean gas and low temperature catalytic converter)

- Reliably achieves the low BREF emission levels for nitrogen oxides (NOx)

Adsorption onto Activated Carbon or Lignite Coke

Both mercury and dioxins/furans can be adsorbed onto activated carbon or lignite coke and then removed from the flue gas.

Depending on the overall flue gas treatment approach, the activated carbon or lignite coke can be introduced and subsequently ejected at different stages of the process:

- In dry sorption (XeroSorp): Introduced into the XeroSorp reactor and removed at the fabric filter (residue discharge)

- In the semi-dry sorption process (HZI SemiDry): Introduced into the SemiDry reactor and removed at the fabric filter (residue discharge)

- In a counterflow process: Injected into the flue gas duct before the fabric filter and removed at the fabric filter (residue discharge)

- In a wet scrubber with a ringjet stage (multi-venturi stage): Injected into the flue gas duct before the wet scrubber, removed at the ringjet stage and finally ejected via the scrubber blowdown

- In a wet scrubber without a ringjet stage (multi-venturi stage): Suspension of activated carbon or lignite coke injected directly into the sump of the packed bed stage; ejected via the scrubber blowdown and removed in a lamella separator

The Main Advantages of Adsorption onto Activated Carbon or Lignite Coke:

- Can easily be integrated into the various processes for removing acid gases (XeroSorp, SemiDry, wet scrubber)

- Very simple system with only a small number of components (storage and conveying)

- Proven technology with a long and successful track record in industry