Zuchwil / Switzerland

Zuchwil / Switzerland

Reducing Volumes of Sewage Sludge while Generating Renewable Energy

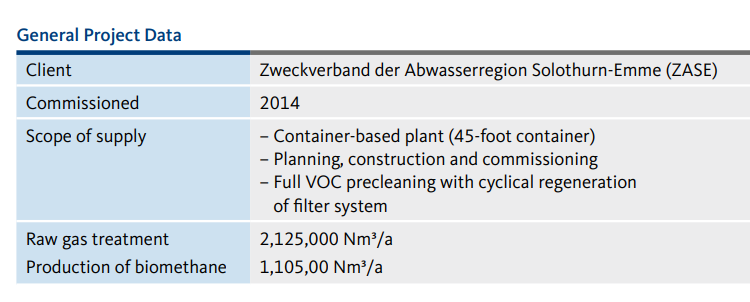

In Zuchwil, ZASE, the organisation in charge of waste water treatment in the Solothurn-Emme area, operates the biggest waste water treatment plant in the Swiss canton of Solothurn. It includes a sewage sludge digester that breaks down organic matter to produce sewage gas. In the downstream membrane gas upgrading unit, featuring efficient precleaning by VOC separation, this sewage gas is upgraded to biomethane with natural gas quality.

Optimised Waste Management

In 2014, ZASE enhanced its Zuchwil facility with the addition of a sewage sludge digester incorporating a sludge water denitrification unit and a gas upgrading system from HZI BioMethan. Bacteria break down the organic component of the sewage sludge in an anaerobic process to produce sewage gas consisting of around 65% methane (CH4) and 35% carbon dioxide (CO2). Zuchwil is the first installation in Canton Solothurn where the decision was made not to burn the sewage gas. Instead it is fed into an HZI BioMethan gas upgrading unit to produce biomethane. The system uses membrane-based gas permeation to separate the carbon dioxide from the methane, which is upgraded to natural gas quality. The biomethane generated in this way is injected into the Regio Energie Solothurn grid. The decomposition process also reduces the amount of sewage sludge that has to be disposed of by around 40%.

Hollow Fibre Gas Separators

The carbon dioxide is separated from the methane in membrane modules with hollow fibres made of high-performance polymer. The sewage gas is introduced into the fibres under pressure. Since the walls of these fibres are impermeable to methane molecules, high-purity methane can be drawn off at the ends of the modules while the carbon dioxide, as well as the hydrogen and nitrogen contained in the gas mix, penetrates the membranes. This interconnected three-phase process produces biomethane of more than 97% purity.

High-Performance Precleaning

Fluctuations in the composition of the raw gas have an impact on the performance and service life of the membranes. To preserve them and prevent the ingress of particulate matter into the gas grid, HZI BioMethane designed an upgrading system with an efficient but thorough process for precleaning the sewage gas. First it is washed, and then it is desulphured in an active carbon filter before being precompressed. A special feature of the plant is the subsequent adsorptive, regenerative raw gas cleaning process. Undesired gaseous components such as volatile organic compounds (VOCs) are adsorbed in filters through a molecular sieve, which prevents them from impairing the membranes and thus keeps them functioning highly effectively. Two adsorbers work alternately in a dual filter system: once one filter is full, the stream of gas is diverted to the second filter, and the adsorber goes into desorption mode. This fully automatic, cyclical process for regenerating the filter system ensures durable and reliable precleaning with varying trace materials. The set-up of the installation draws on more than ten years of experience in planning, building and commissioning upgrading equipment for all types of biogas.