Pommeuse / France

Pommeuse / France

Diversifying Revenues, Boosting Value Creation, Safeguarding the Future

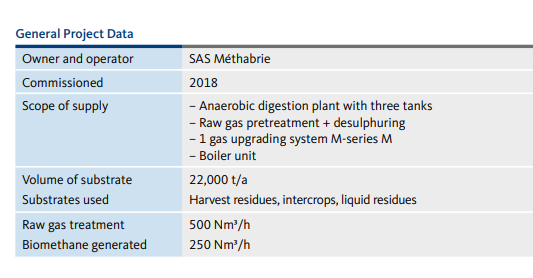

The biogas plant in Pommeuse processes intercrops and agricultural residues from two arable farms. Anaerobic digestion and gas upgrading technology from Hitachi Zosen Inova (HZI) is used to convert 22,000 tonnes of substrate a year into 5,100,000 Nm³/a biogas – this equals 32 GWh of renewable energy – plus high-grade, natural fertiliser.

Farmers as Energy Producers

In 2017 two farmers with adjacent properties in Pommeuse in the Île-de-France region joined forces to invest in a biogas plant with a gas upgrading system. The idea was to assure long-term economic success and the optimum use of

resources. Since then they have been producing and selling biomethane (renewable natural gas) made from intercrop cultivation and other organic residues. This not only makes a contribution to climate protection, but also offers the opportunity to partly replace industrial fertiliser by natural fermentation residues.

Needs-Based Plant Technology

Wet fermentation is the ideal technology for recovering energy from the waste material from agricultural cultivation such as grain, maize, sugar beet or intercrops. Given variations in the substrate, fluctuations in the composition of the biogas and volumetric flow can occur. The control system allows HZI’s flexible gas upgrading technology, which uses membrane-based gas permeation, to be easily regulated to take account of this. The pressure-driven physical process is also impressive in terms of operating costs. The installation was constructed by HZI in its capacity as general contractor with comprehensive interface know-how.

Stable Process

Once fed into the installation the biomass is processed in the PreMix system. This unit, part of the substrate feed-in system, creates a mix of solids with liquid fed in from the digesters, as well as shredding fibrous and solid materials and separating out heavy objects such as stones. The biosuspension, which favours the bacteria culture for digestion, is then pumped into the fermenter: in an anaerobic process bacteria reliably break down the

heterogeneous substrate to produce biogas. As well as facilitating the biological process, pretreatment in the PreMix also makes the matter less tough and thus significantly reduces the electricity consumed by the mixers. Following this first tank the biomass is heated further and fully fermented in a second digester. The residues remain in the post-digester until they are used on the fields as natural liquid fertiliser, as a substitute for industrial fertilisers, which not only saves the operators money but also improves the soil quality of their arable land. The biogas generated is pre-cleaned and desulphured, and then fed into the gas upgrading plant, which separates the carbon dioxide in the biogas from the methane. This biomethane is compressed and fed into the local gas grid.