Jönköping / Sweden

Jönköping / Sweden

Sustainable Transport Fuelled with Recycled Biowaste

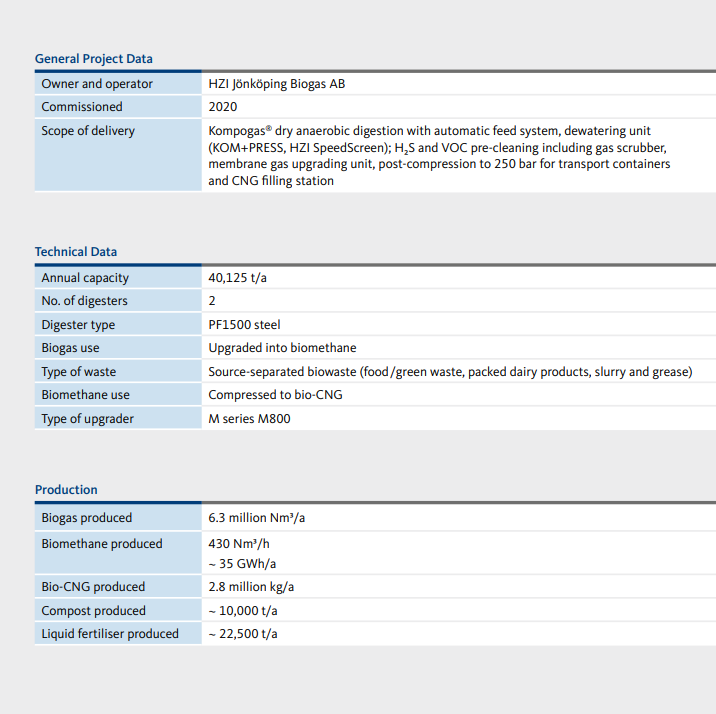

The Kompogas® plant, with a downstream BioMethan gas upgrading unit in Jönköping-Hult, converts organic waste from the region into biogas. Once upgraded and compressed, the gas is available at CNG stations as a green fuel for buses, waste collection trucks and cars. The plant, a prime example of Sweden’s decarbonisation strategy and optimum resource utilisation, also has the potential to produce other types of fuel.

Focus on Climate Protection

By 2045, the Swedish government aims to become one of the first industrialised nations to eradicate the use of fossil fuels and thus permanently reduce carbon emissions. It’s using a combination of a regulatory framework and government grants to drive the implementation of its new energy strategy. A switch to green fuels for local public transport plays a key role. This is precisely where Hitachi Zosen Inova’s (HZI) dry anaerobic digestion plant with biogas upgrading in Jönköping comes in. Organic waste from the provincial capital and surrounding municipalities (around 125,000 residents) is fermented to produce biogas, upgraded into biomethane, and finally compressed to be used as bio-CNG in vehicles running on natural gas. This allows the optimum use of resources and reduces the emissions generated by local public transport by around 15,000 tonnes of CO₂ per year.

Extracting More Value from Waste

HZI’s globally proven Kompogas® technology is used to produce the biogas. The installation, featuring two Kompogas® steel digesters, processes more than 40,000 tonnes a year of green, kitchen waste and food leftovers, plus residual organic materials from industrial and commercial establishments, to produce biogas. At many plants this is converted into electricity or upgraded into biomethane to be fed into the local gas grid. However, the Jönköping-Hult plant goes a step further. It also features a downstream gas upgrading unit which separates the CO₂ in the biogas from the methane by membrane-based gas permeation. But instead of being fed into the grid, the biomethane is compressed and injected into containers as bio-CNG, which is transported to CNG stations in the districts of Torsvik and Ljungarum for use as a vehicle fuel. A total of 52 local buses, 23 refuse collection vehicles – which also deliver biowaste to the plant – and more than 500 natural gas-powered cars in the region now run on fuel produced by recycling biogenic waste. In addition, local farms and gardening businesses benefit from digestate produced from the digestion process in the form of high-grade compost and liquid fertiliser.

From a Problem to a Success Story

The new Kompogas® plant replaced an aging, unprofitable wet fermentation plant operated by the Municipality of Jönköping. In search of better ways of recycling resources, they were impressed by HZI’s proposal: an innovative business model that would maximise circularity in the local economy and preserve existing jobs. The result was HZI’s first DBOO (design, build, own and operate) project in Europe. HZI is the owner of the plant and took charge of design, construction and operation. The project was largely financed by HZI itself and by Klimatklivet, the Swedish government‘s green investment fund.

Thinking Ahead to the Future

With significantly increased waste throughput and a robust digestion process, which is ideal for the production of green fuel, the state-of-the-art plant also has great potential for the future. It’s the ideal platform for expanding production of green fuels using additional HZI technologies. For example, biomethane liquefaction could be used to produce bio-LNG, a renewable fuel for heavy-duty and long-haul transport. Synthetic methane could be made from CO₂ from the biogas upgrading process using power-to-gas technology – for example, by electrolysing water using renewable electricity to produce green hydrogen, this then reacts with the renewable CO₂ from the biogas plant in a catalytic methanation process to produce synthetic natural gas (SNG). This could also be compressed or liquefied and used as a renewable fuel. A plant like this is versatile and expandable enough to produce different renewable fuels, paving the way for the further decarbonisation of the transport sector – currently one of the greatest challenges in global climate protection efforts.