Istanbul / Turkey

Istanbul / Turkey

Waste to Energy: Istanbul’s Contribution to Reducing Global CO₂ Emissions

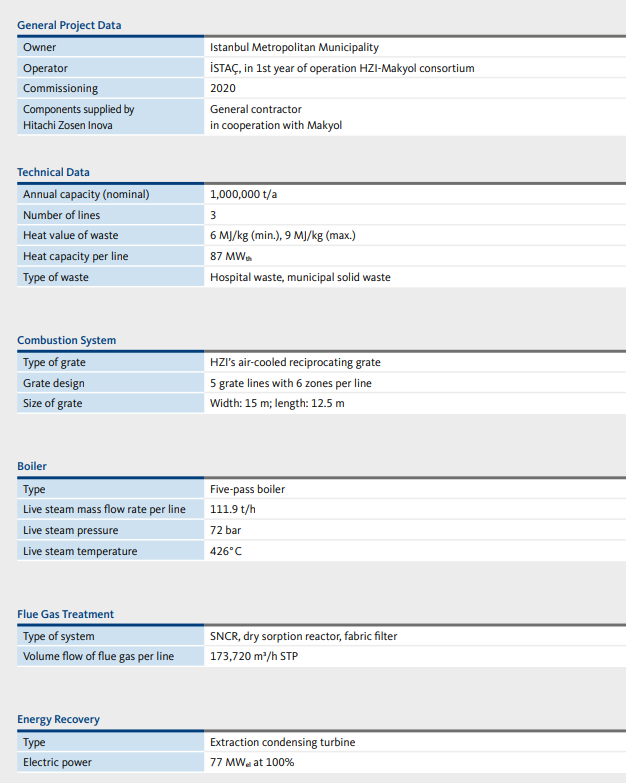

Hitachi Zosen Inova and its Turkish partner Makyol have broken new ground with the construction of Istanbul’s first Waste to Energy project. The plant processes one million tonnes of waste a year to generate around 77 MW of electricity for the city on the Bosphorus.

The project to construct an Waste to Energy (WtE) plant in the Turkish metropolis took several years to develop. Once the contract between the client, Istanbul Metropolitan Municipality (IMM), and a Joint Venture comprising Hitachi Zosen Inova (HZI) and Turkish construction firm Makyol was signed in September 2017, the four-year implementation phase for the largest WtE plant in Europe to date began. The prestigious contract covered the design and construction of the turnkey plant as well as operation and maintenance in the first year. The project received additional support through HZI’s cooperation with the financial service provider AIL Structured Finance

and Swiss Export Risk Insurance to minimise potential currency risks.

Strategic Choice of Location

Whilst the location for many new WtE plants is already fixed from the outset, the Istanbul project required an evaluation of several possible locations. The first stage of the process identified 11 such locations, eight of which were on the European side of the city and three on the Asian side. With such factors as compliance with the applicable laws and regulations, local permit procedures, public acceptance, site accessibility and connections to existing infrastructure taken into account, the number of locations was steadily reduced until the site near the new airport in the north western part of the city was eventually chosen.

Key Infrastructure Project

As of 2021, the plant’s three incineration lines are processing around 15% of the city’s municipal solid waste to generate 77 MW of electricity for its 16 million inhabitants. This exemplary project is part of the Istanbul region’s strategy

for sustainable, environmentally friendly waste management. WtE cuts carbon dioxide emissions by reducing the proportion of fossil fuels used in power generation. Incineration also prevents methane emissions that arise from landfill and are harmful to the environment. The project thus contributes to the global reduction of CO₂ and other damaging emissions. In addition to energy supply and decarbonisation, the new WtE project has also brought economic benefits for the region since its inception. More than a fifth of all its components were produced by local businesses, and all of the staff hired to build and operate the plant were also local.

Precisely Tailored Technology

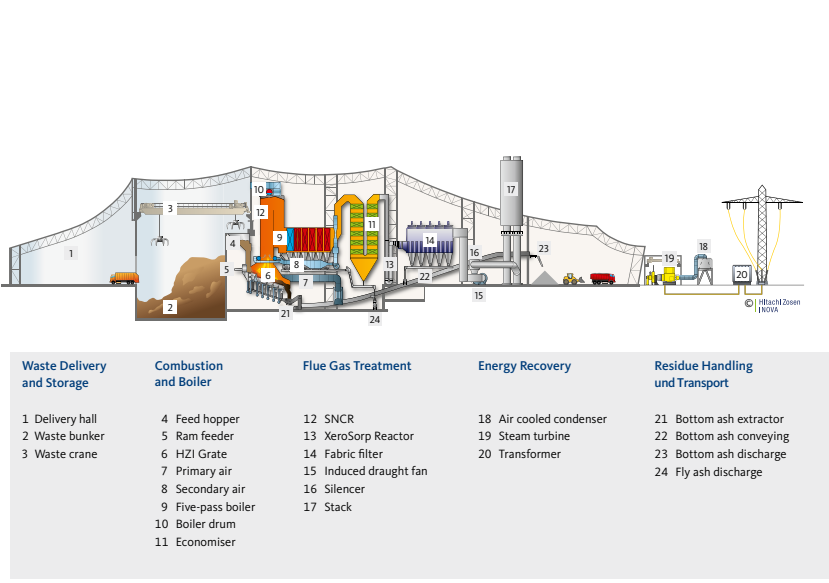

Various factors were instrumental in determining the design of the plant and the technology employed. One of the most important aspects in the planning stage was the composition of the waste to be processed. With this in mind, Istanbul’s waste was studied over a number of years on different days of the week and in several neighbourhoods to arrive at representative values. The plant was eventually designed for waste streams with a calorific value of 6,000–9,000 kJ/kg. The mix of municipal and commercial waste is delivered to the distinctive WtE plant by truck and stored in a bunker. A crane mixes it together and feeds the three incineration lines via a hopper, from which it is conveyed to the HZI Grate by a ram feeder. The grate in Istanbul is very different to those in other European WtE plants: it has an area of 187.5 m2. A fully integrated process control system ensures stable, efficient combustion and optimum burnout on the grate. Following incineration, the bottom ash is removed by a ram extractor in a wet process.

The flue gases resulting from combustion are cleaned in accordance with the most stringent emissions standards in a multi-stage downstream treatment process and continually monitored before being released into the atmosphere via the chimney. The energy from the flue gases is used to create super-heated steam, which expands in a turbine to drive a generator that produces electricity.

Promising Future for Sustainable Waste Management

Istanbul’s first WtE plant is not just a pioneering achievement for the city, it is also relevant in terms of environmental policy. Whereas Istanbul used to send all of its waste to landfill, it is now striving to implement the latest EU environmental rules – no doubt with a view to Turkey’s prospects of becoming an EU member. This bodes very well as regards the market for further WtE plants in the country.