Edinburgh / Scotland

Edinburgh / Scotland

Millerhill Recycling and Energy Recovery Centre: Transforming Regional Waste into Energy and Heat for the Region.

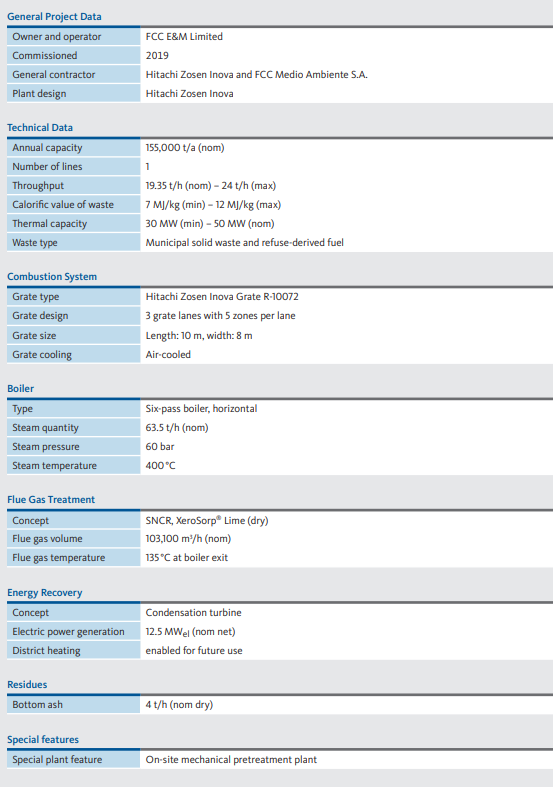

Hitachi Zosen Inova was awarded the contract for a key component of the Millerhill Zero Waste Park in Scotland: The WtE plant treats 155,000 tonnes of local solid waste per year, producing 12.5 MW of renewable electrical energy – enough to supply around 32,000 households. The connection to the district heating network will increase the efficiency of the plant and facilitate reductions in the use of fossil energy resources.

Combined Forces for Scotland’s Zero Waste Plan

Edinburgh’s new Waste to Energy (WtE) plant was procured by the City of Edinburgh and Midlothian Councils under a public-private partnership arrangement with FCC E&M Ltd, a subsidiary of FCC Environment (UK) Ltd. The goal of the project was to deliver a state-of-the-art WtE plant to divert waste from landfill, as targeted in Scotland’s Zero Waste Plan. The turnkey facility, comprising HZI’s in-house combustion and flue gas treatment technologies, was executed by a joint venture between Hitachi Zosen Inova and the Spanish company FCC Medio Ambiente S.A.

Regional Energy

The Millerhill Recycling and Energy Recovery Centre (RERC) processes around 155,000 tonnes of non-recyclable household and commercial waste a year: 135,000 tonnes from the City of Edinburgh and Midlothian Councils, and 20,000 tonnes from other municipal contracts as well as commercial and industrial waste. This results in a thermal capacity of 50 MW, of which over 12 MW electricity is fed into the grid – enough to meet the requirements of around 32,000 households. Besides playing a role in supplying energy to the region, the installation makes a substantial contribution to the implementation of Scotland’s Zero Waste Plan, which targets among other things a recycling share of 70% by 2025 and 95% diversion from landfill by 2025.

Environmentally Sound Process

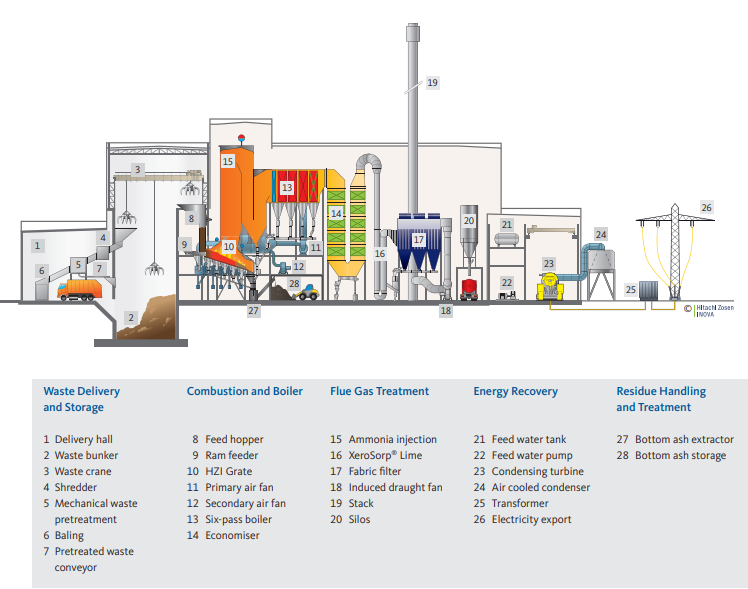

Trucks deliver the municipal waste from Edinburgh and Midlothian to the plant and unload it in the closed delivery hall into the waste bunker. By means of an on-site mechanical pretreatment plant, the waste is pretreated and metals – ferrous and non-ferrous – are sorted out for recycling. The non-recyclable residue is fed back into the bunker and mixed with the delivered RDF (refuse-derived fuels). Ensuring a homogeneous mixing ratio of the waste for best combustion results, the fully automatic, semiautomatic, or manually operated crane system mixes the waste and transports it to the feed hopper. A regulated dosing system ensures even feeding of the HZI Grate, the actual heart of the combustion process. The grate’s hydraulically-driven rows of grate blocks, coupled with the self-regulating primary air supply, ensure ideal burnout of the waste without additional combustibles. The integrated combustion control system regulates heat production and fuel throughput, enabling efficient operation of the plant while at the same time minimising pollutants in the flue gas − even before flue gas treatment. The hot exhaust air from the combustion process flows from the afterburner chamber into the six-pass boiler, where it overheats the water that is fed into tube bundles of the boiler wall. The resulting live steam is directed to the extraction condensation turbine and converted into electricity.

To clean the exhaust gases, the first boiler pass contains a selective, non-catalytic reduction system (SNCR) in which ammonia solution is injected as a reducing agent to reduce the nitrogen oxides. In a second step, the installed XeroSorp® dry flue gas treatment system removes the acidic exhaust gases by adsorption, at the same time reducing the water consumption of the plant and the quantity of additives. The strict emission limits are thus undercut in a cost-efficient and environmentally friendly manner.

Heat Export for Augmented Efficiency

According to the Scottish Environment Protection Agency (SEPA), new WtE plants must have a solution for their heat offtake within six years of operation. Therefore, and in alignment with the Millerhill Low Carbon District Heating Project, RERC was designed with the option of exporting heat to the local district heating grid. A district heating scheme for the “new town” that will surround Millerhill to the south and west has been developed by the City of Edinburgh and Midlothian. It will be fully supplied by the heat generated at RERC.